With the continuous improvement of urban infrastructure, water supply and drainage systems have become an indispensable and important part of urban operation. However, ground leakage pipe problems occur from time to time, not only affecting the normal life of residents, but also may cause adverse effects on the environment of the city. Therefore, it is particularly important to repair the ground leakage pipe problems. In this paper, a set of systematic and comprehensive ground leakage pipe repair strategies will be introduced in detail, aiming to quickly and accurately locate the leakage point through scientific methods and take appropriate repair measures to ensure the normal operation of the pipeline system and provide a solid guarantee for the sustainable development of the city.

I. Strategy Overview

Aiming at the current leakage problems of surface pipelines, this repair strategy aims to ensure the normal operation of water supply, drainage and ventilation systems through a systematic approach. The rehabilitation process will be divided into six key steps: diagnosis, precise location, excavation preparation, implementation of the rehabilitation, functional testing, and backfill restoration.

Diagnostic stage

1. Check the historical operation records of the pipeline to understand the state of use and historical maintenance of the pipeline.

2. Carry out water pressure test on the suspected leakage area to make a preliminary judgment on the approximate location of the leakage point.

3. Carry out detailed inspection of the pipeline, observe whether there are signs of damage and corrosion in the appearance of the pipeline, and at the same time assess the influence of the surrounding environment on the pipeline.

III. Precise localization

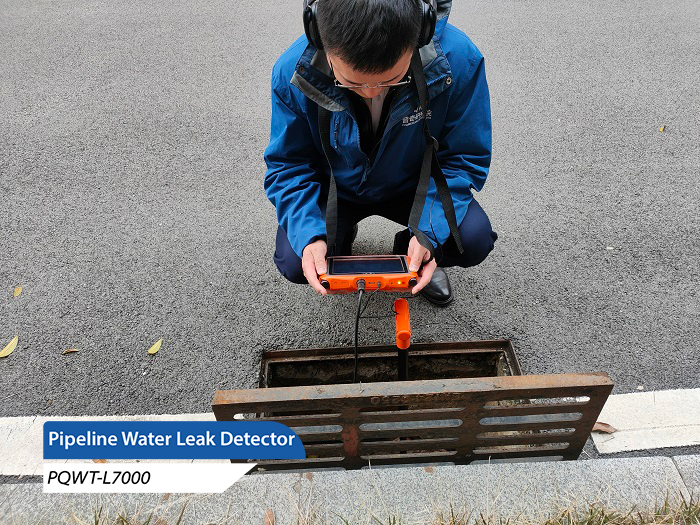

According to the results of the diagnostic stage, use the advanced pipeline leak detector to accurately lock the specific location of the leakage point, and assess the degree of damage to the pipeline.

IV. Excavation preparation

1. After determining the location of the leakage point, plan the excavation area to ensure that the scope of excavation is sufficient to expose the damaged part of the pipeline.

2. Arrange personnel to clean up the excavation area and remove obstacles that may hinder construction.

3. Set up safety warning signs to ensure the safety of the construction site.

V. Implementation of Repair

According to the damage of the pipeline, use one or more of the following repair methods:

1. Polymer seal coating method

Use special polymer sealing coating, directly painted on the leakage, using the sealing and adhesion of the coating to achieve rapid repair.

2. Copper welding method

For pipe corrosion or fracture, copper welding rod is used for welding repair to ensure the structural integrity and firmness of the repaired pipe.

3. Expansion filling method

Use special expansion filling material to fill the holes and gaps inside the pipe, and realize the sealing inside the pipe through the expansion nature of the material.

Functional test

1. After the repair is completed, conduct water pressure test on the pipeline to ensure that the pipeline has no leakage phenomenon.

2. Conduct a comprehensive inspection of the repair parts to ensure that the repair quality meets the standards.

3. After the test to confirm that there is no error, before entering the next stage.

Seven, backfill restoration

1. Clean up the restoration area and backfill the excavated soil and rock to the top of the pipe.

2. Use professional tools to compact the backfilled soil and rocks to ensure that the pipeline will not be displaced due to inaccurate backfilling.

3. Level the backfilled area to make it consistent with the surrounding ground.

Through the above seven-step repair strategy, you can effectively solve the problem of ground pipeline leakage to ensure the normal operation of the pipeline system.